The opening panel of our event in Munich, The Future of Defence Tech Manufacturing & Innovation, featured Nataliia Kushnerska, CEO of BRAVE1, Sille Pettai, CEO of SmartCap, and John Ridge, Chief Adoption Officer, NATO Innovation Fund. It was moderated by Liz Young McNally, Deputy Director, Commercial Operations, Defense Innovation Unit.

This discussion highlighted the urgent need for faster, scalable, and more innovative defense manufacturing across Europe. Ukraine is rapidly developing and deploying innovative wartime technologies, Estonia’s SmartCap and the NATO Innovation Fund are investing in future-ready solutions. However, procurement inefficiencies, supply chain vulnerabilities, and outdated financial models remain major barriers. Collaboration between governments, startups, investors, and academia will be key to reshaping European defence manufacturing for the future. Excerpts from the panel, which you can watch on our Youtube Channel, are below.

The Future of Defence Tech Manufacturing & Innovation, was presented by the US Defense Innovation Unit and Munich Security Conference Tech & Innovation Thursday, sponsored by Boston Consulting Group, and powered by Resilience Media.

Historical Framing

Sille Pettai, CEO of SmartCap: “[Putin] rolled out massive support programs for industrial companies to modernise production, and not just the defence industry, but also the whole supply chain from steel mills and critical materials to manufacturing of machinery. There were grants for innovation, there were tax incentives, there were subsidies to loans. The industrial companies…actually modernised their production, so in 2022 they were really well geared for the war. And that’s what we see now. We really want to see them weak, but … they were quite well prepared. And that’s the industry we are facing on the border of Russia. We can’t build a defence industry like that in Estonia.

Nataliia Kushnerska, CEO of BRAVE1: “…[T]he war in Ukraine shows us that we are not ready for the war. All our manufacturing is scaled up only to refill the stocks. All our innovation … [is] far away from the real needs and from the real number of the things. And within the war, only in Ukraine, again, all Europe is not ready to deliver the number of the things needed within frontline.”

John Ridge, Chief Adoption Officer, NIF: “[T]he Mosquito aircraft that was designed in World War II was … made of wood, and it was made of wood because you could then put all those component manufacturers out to artisan tradespeople and get them to make the individual components and assemble them later. [Y]ou kind of work with the industry base you’ve got rather than the one you wish you had. So an example there, it was also made multi-role so that you could adapt it to different sorts of missions. [W]e’ve been here before and we get there eventually when we get into a war. My frustration is I’d much rather get there now and start to have the discussions around…what things could we scale once we’re actually in the conflict? Therefore, what does our force mixture look like halfway through the conflict? Therefore, how do we then start to build our understanding of how do you move from your existing force structures to those new force structures?”

The Role of Defence Innovation Clusters and Investment Funds

John Ridge outlined three characteristics the defence industry will need to have in the next five years: sovereignty, redundancy, and to support innovation. Western Europe needs to be able to support innovation and business models that allow companies to harness it.

Ridge said, “we’re not there yet because exactly as has been said before, our systems are configured for ‘let’s buy this thing in 10 years time…Let’s have a single provider doing it all.’ We’re not going to win the war with that.”

Strengthening European Defence Manufacturing

Sille Pettai: “We wanted so bad for Russia to be weak, but they spent years modernising their production.” Russia prepared for war well in advance by strengthening its industrial base post-2014. Estonia must rely on software-driven, AI-enabled defence solutions rather than traditional manufacturing.

John Ridge: Sovereignty, redundancy, and agility are key. “You start your war with your arsenal, but you win it with your manufacturing base.”

The Future of Defence Manufacturing

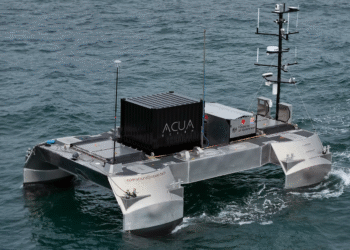

Sille Pettai: “We used to have a macaroni factory in Tallinn, Estonia, where you could make slight adjustments to produce bullets. I think those times are over. And all these CNC benches or 3D printing machines you can use for pretty much anything. And that’s part of the peacetime business plan and peacetime production as well. You don’t need to produce enormous amounts and volumes of drones or other innovative equipment to your warehouses, but you can roll out the manufacturing really quickly. It can be mobile, often in containers, and bring down the cost. So you don’t really need to keep these expensive machinery and production lines waiting for the production or producing all the time. And once you need it’s outdated. Nobody’s going to use the [products] that you produced into the warehouse.”

Barriers to Scaling Defence Tech

Sille Pettai: Fragmented and outdated procurement processes create a ‘manufacturing Death Valley’ for startups. “The entry barrier is extremely high. It’s not about lack of funding, but about how hard it is to secure contracts and scale manufacturing.”

John Ridge: Dual-use companies struggle with supply chain vulnerabilities. “We need to know exactly where our components come from. Cheap drone motors are mostly sourced from China, creating a security risk.

Nataliia Kushnerska: Manufacturing at scale is a major challenge. “To supply 5,000 robotic systems, we need 30,000 wheels. How many factories can produce that fast enough?”

The Role of Governments, Academia, and Finance

Nataliia Kushnerska: Science, engineering, and R&D teams must be better integrated into defence innovation. “A little bit of bravery, a little bit of ambition, and a lot of good people—this is how we build the future.”

Sille Pettai: Procurement and government processes must be streamlined to allow startups easier entry. “Defence contracts are so complicated that many startups don’t even try.”

John Ridge: “There’s the need to provide [startups] ways to get non-dilutive funding. So we take equity and I think you get to a certain point and for companies — quite reasonably — they want to retain the equity that they’ve got.”